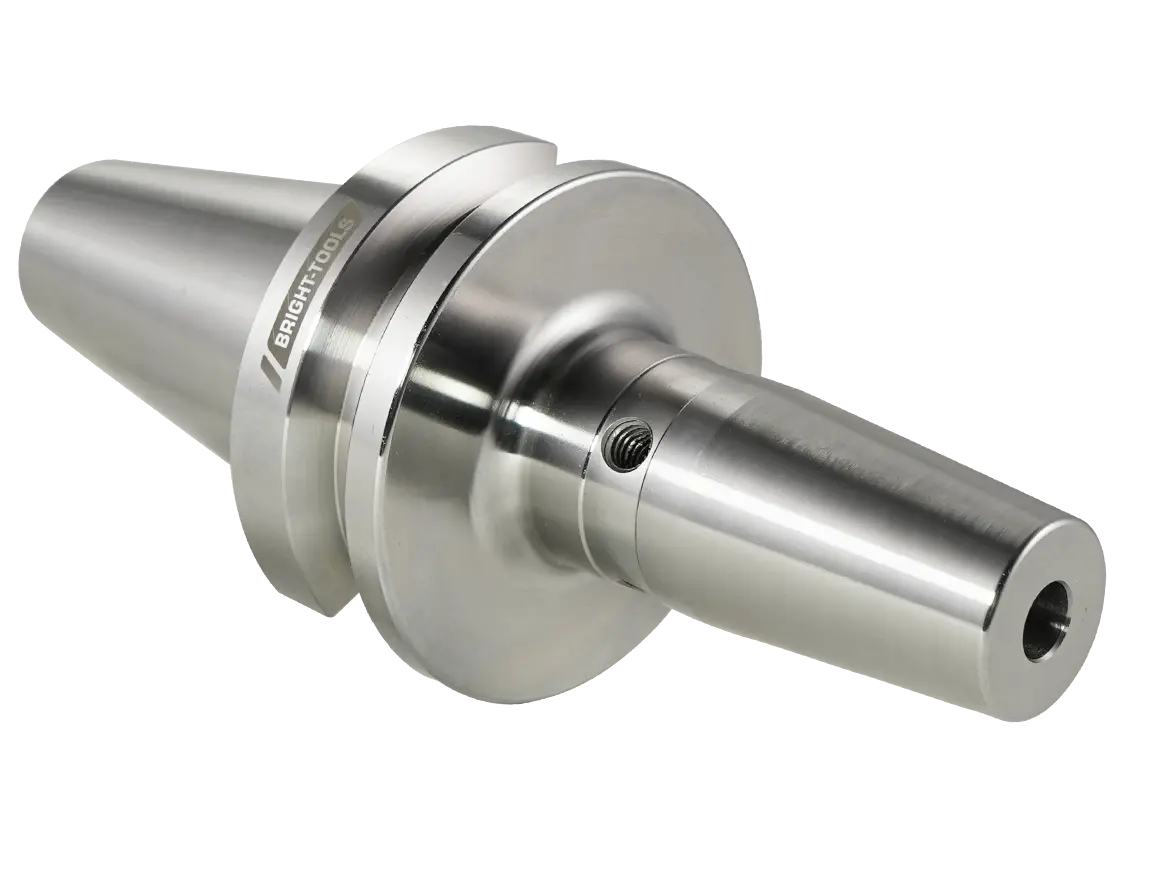

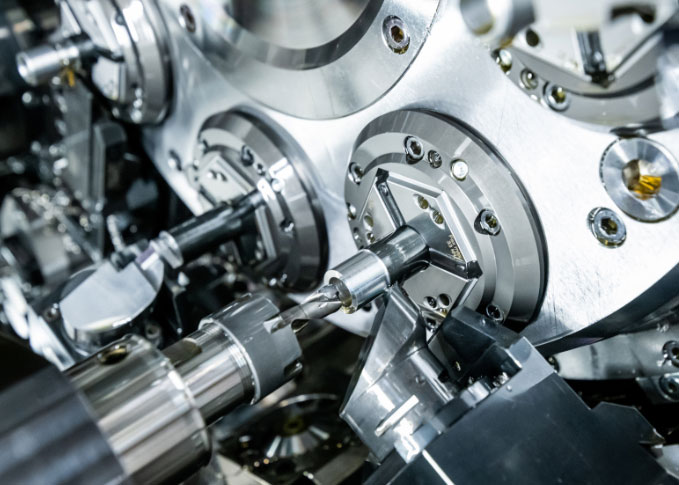

HOW DOES A CNC TOOL HOLDER WORK?

CNC Tool holder is a device to provide a critical interface between the cutting tool and the CNC machine spindle. So, when a CNC tool holder is connected to spinle and the cutting tool, we can do the machining process with kinds of CNC cutting tools such as drill bits, end mills, face milling cutters, etc.

More Technical Help: Working principle of hydraulic tool holder

English

English  日本語

日本語  한국어

한국어  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  português

português  tiếng việt

tiếng việt  Türkçe

Türkçe  فارسی

فارسی  zh-CN

zh-CN